-

iSoftStone Consulting Financial Company Integrated Global Solution Group Treasury Solution e-CNY Smart Contract Platform AISE Products Non-Car Insurance Core Business System Solution Health Insurance Core Business System Solution Industrial Internet of Things (IIoT) Application Solution Power Production Supervision and Online Operations System Solution Retail Business Middle Office Solution Data Governance Solution Multi-Cloud Management Platform Solution AI-End Cloud Integration Solution USP Unified Service Platform Solution Digital Intelligence Supply Chain Solution Industrial Metaverse Solution Merak 2.0 MaaS Multi-Modal Large Model Operation Platform CloudVC Solution

-

- Communication equipment Mobile terminal manufacturers

- Telecom operator Internet

- High technology Manufacturing

- Bank Insurance Finance company Capital markets Internet finance Corporate finance

- Transportation and logistics Retail and Fast-Moving Consumer Goods (FMCG) Digital Energy Real estate Great Health Industry

|

|

|

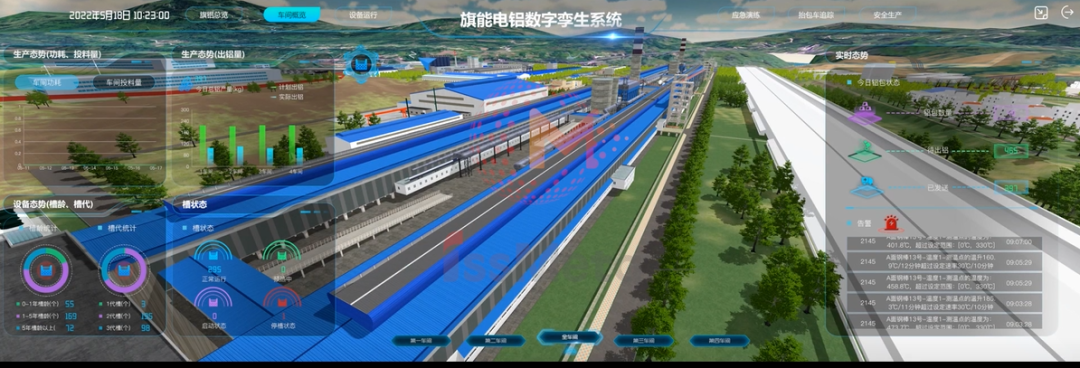

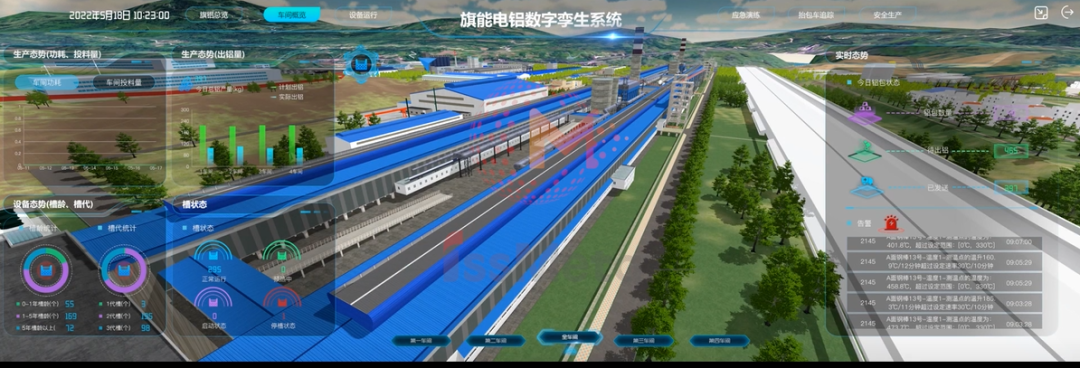

Project Background: Energy Banner is the largest electrolytic aluminum supplier in the Chongqing region, with the highest degree of integration of informatization and industrialization. To promote intelligent manufacturing transformation, the company needed a system to showcase smart factory capabilities, monitor production status, and visualize the overall environment, production workshops, equipment, and safety-critical monitoring areas. Through the interconnection of equipment, the goal was to digitize the production equipment in the workshop, upgrading it from the previous standalone mode to a digitized, networked, and intelligent management mode.

Project Outcomes: It achieved precise digital mapping of the physical plant area and comprehensive reproduction of equipment production elements. It supported 90 days of continuous safe production in the electrolytic aluminum workshop during the first quarter of 2022, ensuring that safety and production operation indicators were achieved 10 days ahead of schedule under the pressure of the epidemic. This ensured the supply guarantee of primary aluminium in Chongqing during the first quarter of the epidemic. Additionally, Energy Banner achieved a 10% increase in primary aluminium production compared to the same period last year in the first quarter. |